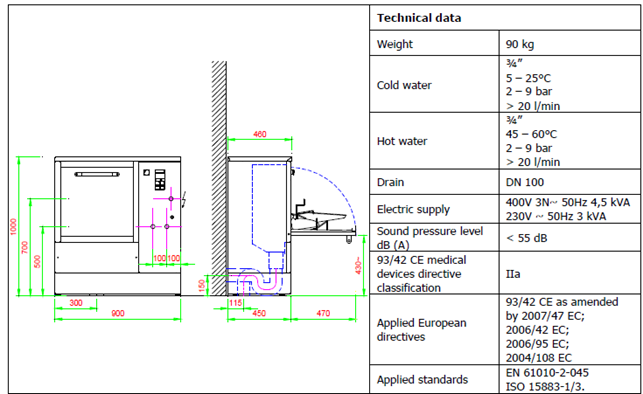

MODEL MET-LPIN90-S

MODEL MET-LPIN90-S

AUTOMATIC BEDPAN AND URINAL WASHERS

SELF-PRODUCED STEAM DISINFECTION

Automatic washer-disinfector for human waste containers.

Manual operated folding door. Wash system by rotating and fix nozzles. Container supports with rapid replacement system. Free standing or wall mounted execution.

Options:

- Wide range of special supports

- dosing pump for wash/rinse additive

- dosing pump for final rinse additive

- blocked drain sensor

- sink with mixer tap and hand shower

Device operating with a water network pressure ranging between 2 and 9 bar. Equipment specifically built to empty, wash, rinse, thermally disinfect and partially dry Bedpans and urinals. Structure in AISI 304 stainless steel.

Main element with a front folding door, controlled by shock absorbers. Bedpan hooking and locking bedpan device suitable for all types of bedpans and clinical containers, mounted on the door and meant for emptying during the closure. An electro-lock is intended to prevent the operator from opening the door during the operation or in case of failure. Stainless steel AISI 316 washing chamber molded without weld equipped with 2 rotating nozzles and 4 fixed nozzles stainless steel meant for washing and rinsing bedpans. Independent jet for washing urinals internally and externally. Steam delivered by a proper nozzle. Water storage tank having a capacity of 15 liters, with electronic probe level.

Side element including the solenoid valves for the inlet of hot and cold water from the water network, electronic central unit for function control, remote control switch of resistances for steam production. Front panel with a back lighted alphanumeric liquid crystal display complete with a cycle start key, a key for the selection of cycle options and two keys for programming functions, a serial plug intended to download stored data with (temperatures, failures, number of washings, cycle date/time). Mushroom-shaped emergency button with a manual lock and reset device. Power supply of control devices at a 5V dc very low safety voltage. Steam producer and safety thermostat that can be manually reset, Geberit drain trap Ø 90 mm. anti-limestone liquid drum with aspiration and a minimum level control, anti-limestone liquid dosing pump. Washing motor- driven pump 0.8 kW 230V.

The automatic washing, rinsing and disinfecting cycle, with the possibility of time regulation, is electronically programmed. It consists of the following phases that are automatically executed after the start button has been pressed:

- Loading cold water in the storage tank

- Washing with cold water

- Loading hot water in the storage tank

- Rinsing with hot water

- Steam disinfection with automatic calculation of Ao and following drying

- cooling the containers by cold water

TEMPERATURE

The system, as required by the ISO 15883, it is endowed with a double sensor of temperature (process sensor and control sensor), which provides to signal the anomaly in case the read temperatures differs of 120C, besides the operator can choose to perform the cycle with priority to temperature or priority to Ao value, moreover can set the Ao value and the temperature of disinfection.

With the priority method Ao, the equipment calculates the instant value during the phase of temperature rising, and it arrests the disinfection to the attainment of the preset Ao value (the Ao value established by the norm for human waste containers shall be at least 60). The cycle with temperature priority foresees that the disinfection is performed up to the attainment of the temperature and the time settled, at the end of which the Ao value reached is showed on display card, which has to be equal or superior to the value planned.

DETERGENT PUMP

The pump, after the programming of the output time and determinate the water quantity in the tank, add directly in the tank the detergent/disinfecting. The function can be enable and/or disenable directly from display on the follow phases:

Pre-wash, wash and rinse only rinse

PUMP RINSE AID

The pump, after the programming of the output time and determinate the water quantity and hardness in the tank, add directly the polishing for the phase of the final rinse, improving the phase of the drier and the elimination of the residual limestone. The function can be enable and/or disenable directly from display.

DYNAMIC DRYING

At the end of the disinfection phase a steam damp in the chamber is performed, followed by the partial opening of the door to help the drying for condensation. The system is very effective in combination with the rinse aid pump (see Note 3)

ACCESSORIES